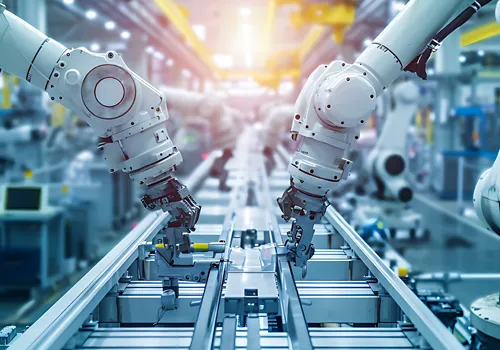

Odoo Manufacturing App enhances your production workflow with real-time work order tracking, scheduling, quality control, and maintenance management. By optimizing operations, minimizing downtime, and boosting product quality, it offers a flexible and integrated solution.

Easily create and oversee manufacturing orders, ensuring all production activities align with your schedule. Odoo software provides a detailed and user-friendly view of your MO status, allowing you to track progress and make real-time adjustments.

Efficiently handle work orders by assigning, tracking, and completing tasks. With Odoo's work order management, you can monitor workstations, operators, and deadlines to maintain a seamless production flow.

Accelerate and simplify your manufacturing processes through barcode scanning. Odoo software barcode integration allows for quick and precise tracking of materials and products at every production phase, minimizing manual data entry errors.

Manage repair orders effortlessly to keep track of maintenance, quality checks, and repairs on your manufacturing equipment or products. Odoo ERP software assists in scheduling repairs and ensuring that proper service is performed without interrupting your production timeline.

Make adjustments to manufacturing orders as necessary. Odoo manufacturing app provides the flexibility to modify MOs to reflect changes in inventory, production needs, or customer demands, ensuring your production line operates smoothly and efficiently.

Easily monitor and manage unbilled orders. Odoo helps you ensure timely invoicing by keeping track of orders that have yet to be billed and ensuring everything runs smoothly.

With Odoo software, you can effortlessly plan your manufacturing activities, ensuring that production processes align with demand. The system assists you in managing schedules, allocating resources effectively, and making informed decisions to meet deadlines and production targets.

Streamline the organization and management of work orders. Odoo system allows you to plan, schedule, and assign tasks to the appropriate resources, ensuring work orders are completed accurately and on time. Monitor progress and make necessary adjustments for a seamless production flow.

Easily create and manage your Bill of Materials (BOM). Odoo manufacturing app helps you plan and keep precise records of all raw materials, components, and resources needed for each product, ensuring you have everything required for production without errors or delays.

Maximize your production capacity by effectively managing workcenter resources. The Odoo system enables you to track the availability of workcenters, allocate them based on priority, and balance workloads, helping you avoid bottlenecks and improve overall efficiency.

Odoo’s adaptable master data management features enable you to adjust and expand your manufacturing processes seamlessly. Whether creating multi-level Bills of Materials (BOM) or handling version changes and optional routings, Odoo manufacturing app keeps your production data organized, dynamic, and efficient.

Odoo software creates multi-level BOMs that simplify complex manufacturing processes. You can specify the components, subcomponents, and raw materials required at each production stage, ensuring accuracy and efficiency throughout the supply chain.

Optional routing introduces flexibility into your manufacturing operations. Odoo business solutions allows you to define various routes for production, enabling you to select the best option based on work center availability, lead times, and cost efficiency.

Manage version changes in your BOMs and routings with ease. Odoo ERP assists you in tracking updates and revisions, ensuring that your team always has access to the latest version of a product or process, which helps minimize errors and maintain consistency across all manufacturing stages.

Odoo facilitates the creation of kits—predefined groups of products that can be assembled. This feature is handy for producing bundled products, configuring items in specific ways, streamlining inventory management, and planning production effectively.

Odoo’s Product Lifecycle Management (PLM) features help you efficiently oversee product development from the initial concept to final production, fostering better collaboration, innovation, and control over your products.

Odoo's versioning feature enables you to manage and track various versions of product designs and BOMs. Each version is documented with visible changes and revisions, ensuring your team always has access to the latest designs and specifications.

Odoo's integrated PLM system centralizes all product-related data, including specifications, drawings, and changes. This seamless integration with other manufacturing processes improves coordination between design, engineering, and production teams, ensuring all product information is accurate and up-to-date throughout its lifecycle.

The Odoo manufacturing app streamlines the management of engineering changes. It monitors edits in product design, components, and BOMs, automatically updating the necessary documents and production plans. This guarantees that changes are accurately implemented and communicated to all stakeholders, minimizing errors and enhancing production flow.

Access CAD files, technical specifications, quality documents, and other essential information to facilitate smooth collaboration across teams and departments. With Odoo's comprehensive document management system, you can store, organize, and manage all product-related documents in one centralized location.

Set and handle quality control points at different phases of your production process. Odoo ERP enables you to set inspection criteria and confirm that products meet your established standards, ensuring that only top-quality items proceed in manufacturing.

Conduct thorough quality checks during manufacturing to guarantee compliance with standards. Odoo software allows you to automate the scheduling of quality inspections, whether for raw materials, work-in-progress, or finished goods, ensuring a holistic approach to quality control.

Odoo system alerts you to any quality issues in real-time, enabling you to swiftly identify and resolve potential defects or discrepancies in the manufacturing process. With customizable alert systems, you can prevent defects from advancing further down the line, minimizing scrap rates and enhancing overall product quality.

Odoo ERP's preventive maintenance feature helps minimize unexpected breakdowns and extends the life of your assets. It allows you to schedule regular maintenance tasks for your equipment and machinery based on usage, time intervals, or other customizable criteria. This proactive strategy helps prevent costly repairs and production delays.

In equipment failure, Odoo manufacturing app enables you to swiftly create and manage corrective maintenance requests. By documenting issues and overseeing the repair process, you can ensure minimal disruption and a quicker turnaround, getting your production line back up and running as soon as possible.

Odoo's calendar integration helps you seamlessly schedule preventive and corrective maintenance tasks. The visual calendar provides an overview of upcoming maintenance tasks, allowing you to plan and coordinate work efficiently and avoid conflicts with other production schedules.

Track downtime, repair history, and the overall effectiveness of your maintenance strategies. This data-driven approach empowers you to make informed decisions that enhance maintenance routines and lower operational costs. With Odoo's maintenance statistics, you can gain valuable insights into your equipment's performance.

Equip your production team with tablets to access work orders and production data while moving. The tablet interface lets operators quickly check tasks, scan barcodes, and update statuses, ensuring everyone stays aligned with minimal paperwork.

With Odoo's Work Control Panel, operators can record production data directly at each process step. They can monitor output, timesheets, and work progress in real-time, ensuring that production records are accurate and up-to-date, which helps streamline operations and reduce errors.

Detailed worksheets guide operators through every phase of production. Odoo manufacturing app's customizable worksheets present instructions, materials, and operations needed for each task, ensuring consistency and minimizing errors during the manufacturing process.

The Work Control Panel also manages miscellaneous operations like rework, scrap, or quality checks. You can easily create and oversee non-standard tasks to ensure that all production activities are documented and tracked, no matter their nature.

Keep your production flow on track with built-in alerts for deviations, delays, or critical issues. These notifications enable teams to quickly address problems, reducing downtime and ensuring smooth production processes.

Clearly defined work order steps are shown for each operation. Odoo system's Work Control Panel allows production teams to follow a structured, step-by-step process, ensuring manufacturing efficiency, accuracy, and consistency.

Monitor every product and material throughout the manufacturing process, ensuring complete visibility and compliance with regulations.

Evaluate production costs, identify inefficiencies, and optimize resources to enhance profitability.

Track machinery performance to minimize downtime, increase output, and maximize equipment efficiency.

At Greytrix Business Solutions, we implement Odoo Manufacturing to streamline production processes and enhance efficiency. With features like work orders, BOM management, and real-time tracking, Odoo Manufacturing integrates seamlessly with inventory and quality apps, ensuring optimized production, reduced waste, and improved operational control.